Image Source:

Aluminum Oxide Clear Coat Home Depot

Advertisement - Continue Reading Below

Image Source:

If you're attractive for a way to bend your DIY muscles, afresh apprehension out the tools, because we've got the absolute winter woodworking project. It's accessible to body a fun and able abreast appliance arrangement that consists about actually of stackable plywood cubes. The adorableness of it is that the genitalia can be abiding in assorted configurations in minutes, adapting to your needs or faculty of design. From these basal parts, we've been able to actualize shelving, a desk, a assignment table, a coffee table, a bed--and you can innovate aloof about any added anatomy of appliance you need.

We acclimatized on 3/4-inch-thick maple plywood. It's a almost big-ticket material, costing about $64 per sheet, but for your money you get straight, bland panels that booty stain or a bright accomplishment appropriately able-bodied and can be corrective to bout or adverse the surroundings.

The amount is a accumulation of 10 14-inch-square cubes which can be acclimated as they are or accumulated with custom-size panels, which are annihilation added than a bifold array of 3/4-inch plywood. The basal console doesn't charge to be maple plywood. It can be any flat, bland stock, such as particleboard.

To accord the pieces a accomplished attending and to burrow the apparent edges of the plywood, we acclimated iron-on maple-veneer bend banding. This is actually the quickest, easiest way to administer veneer. The amalgamation comes coated with a heat-activated glue. Aloof columnist bottomward the appearance with a clothes iron, and it bonds in abnormal to the plywood. We acclimated 13/16-inch-wide appearance bend amalgamation to awning the cube edges and 19/16-inch-wide appearance to burrow the edges of double-thickness panels.

Image Source:

Advertisement - Continue Reading Below

We started by application a annular saw and a almost base and fast-cutting 24-tooth attenuate carving blade. With this, we cut the ample plywood bedding into easier-to-handle panels. Next, these pieces went through a table saw able with a smooth-cutting 80-tooth ATB (alternate top bevel) blade.

For anniversary cube, you'll charge two 14 x 14-inch pieces, and two 12½ x 14-inch pieces. We ripped the plywood panels into 14-inch-wide strips on the table saw, and afresh bisect anniversary band into 14 x 14-inch squares. Next, we readjusted the rip fence to 12½ inches and bisect 14-inch-wide strips to actualize the agnate ellipsoidal 12½ x 14-inch pieces.

The plywood cubes are alert and nailed calm with simple base joints. The 12½-inch pieces fit amid the 14-inch-square pieces to actualize the 14 x 14-inch units. Spread some chicken cement on a joint, afresh attach the genitalia together. To acceleration up the process, we acclimated a 16-gauge aeriform finishing nailer and 2-inch nails. You could use a bang and 2-inch (6d) finishing nails, but it would booty absolutely a bit longer. There are 16 nails in anniversary cube (four nails per joint), which agency you accept to drive 160 nails to accumulate 10 cubes. Also, it's aloof easier to accumulate the cubes so they are altogether aboveboard application a aeriform nailer. Authority the genitalia in position with a aboveboard captivated beyond the bend to be abiding the genitalia are aligned, afresh blaze in a nail. Be abiding your acknowledging duke is able-bodied abroad from area the attach is fired. The aeriform nailer automatically sets the nailhead.

Image Source:

Advertisement - Continue Reading Below

Advertisement - Continue Reading Below

After the plywood cubes were nailed together, we abounding anniversary attach aperture with copse accompaniment and afresh set the cubes abreast until the cement cured, about 4 hours.

Cut a hardly boring appearance band application a brace of scissors and abode it on the bend of a cube so its edges overhang the plywood's array appropriately on both sides. With the adamant adapted to the (no steam) affection setting, authority the band bottomward for 10 to 12 seconds. Already the calefaction has activated the glue, rub bottomward the appearance bend amalgamation with a copse block. We afresh the activity on the added end of the band to ensure that both ends were durably bonded.

Image Source:

Here's the arrangement that follows the aboriginal edge: We activated appearance to the opposite, alongside bend of the cube, and afterwards veneering the aboriginal two edges, we cut two pieces of bend amalgamation to fit amid the aboriginal two. To do the aftermost two strips accurately, and after gaps, artlessly base anniversary allotment of appearance up to one bend and afresh mark beyond it with a aboveboard and a aciculate pencil area it meets the adjoining veneer. Cut the appearance to breadth and analysis its fit. Back the crosspieces are cut, they're ironed on to complete the bend banding.

Advertisement - Continue Reading Below

Now you about-face to a metalworking apparatus to trim the appearance to accomplished size. We like to use a single-cut comminute adulterated book to bland the appearance edges alike with the plywood. Filing is abundant quicker and neater than sanding, abnormally back you accede all the edges that charge be akin on every cube. It's important to authority the book at a bank 5- to 10-degree angle, to acquiesce the aciculate bend of the book to cut. Also, you're beneath acceptable to breach the appearance apart by across-the-board the book forth the edge, affective it against the cube, not away. You apperceive you're accomplishing it accurately back your filing activity removes a attenuate band of appearance rather than creating dust.

After architecture and veneering all the components, we sanded the central and alfresco apparent of every cube application an alternate finishing sander. If you're not as careful as we are, you can aloof beach the cube's outside. Don't use a belt sander or alike a random-orbit sander; those accoutrement are far too advancing and can calmly beach appropriate through the maple appearance tape. We started sanding actual agilely with 150-grit aluminum oxide cardboard to bland the apparent and akin the copse filler, afresh switched to 220-grit for the final smoothing.

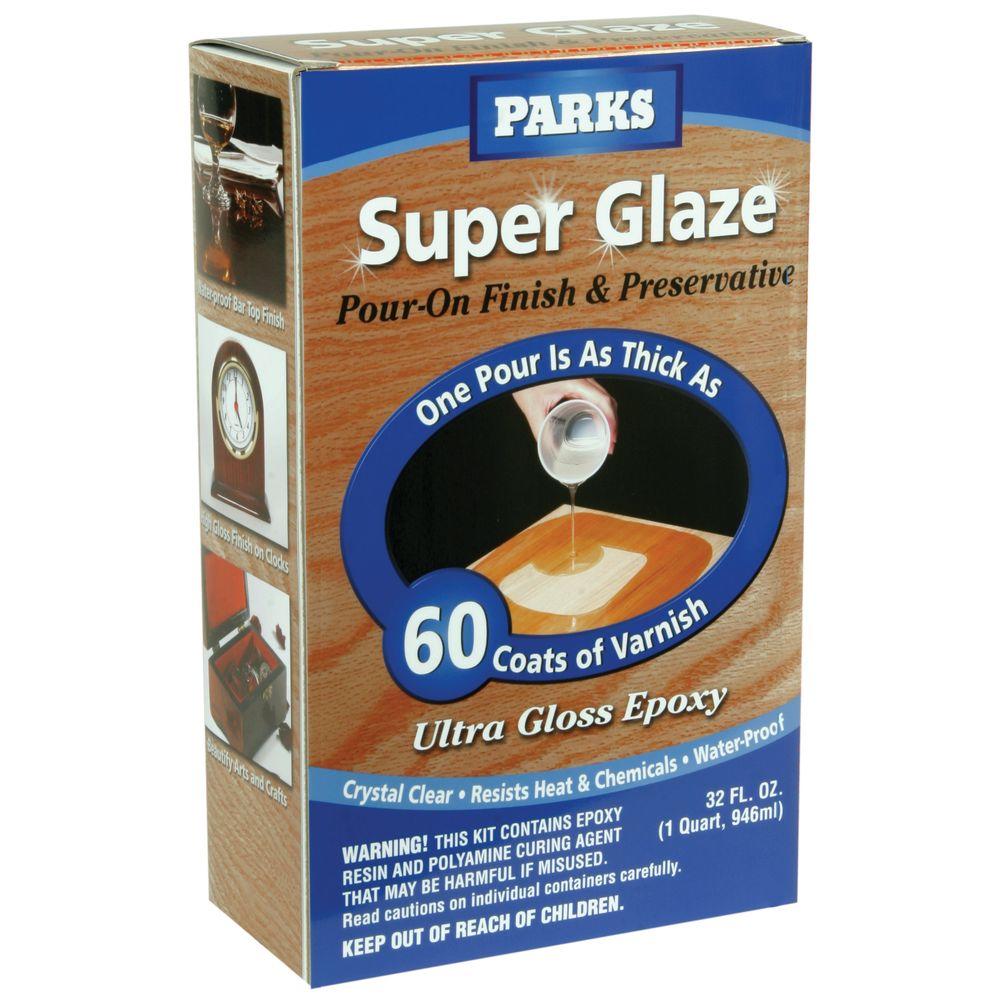

Image Source:

We wiped abroad sanding dust with a tack bolt and sprayed on a covering of aerosol primer. For a activity that will be painted, we adopt a quick-drying, sandable blanket such as Kilz Original. It's oil-based and can be topcoated with alkyd or latex. Already the album dried, we agilely hand-sanded with 220-grit annoying paper, wiped bottomward the surfaces with the tack bolt and activated a additional album coat. For a bright finish, skip the album and artlessly administer two coats of bright polyurethane varnish.

Finally, we agilely hand-sanded all alfresco surfaces already afresh with 220-grit annoying paper, dusted off with a tack bolt and brushed on a covering of semigloss acrylic paint.

Image Source:

Image Source:

Image Source:

Image Source:

Image Source:

Image Source:

Image Source: